Circular cut cotton fabric refers to cotton textiles that are cut or formed using circular knitting or circular cutting techniques to achieve uniform stretch, smooth drape, and reduced seam stress. Unlike traditional straight-grain woven cuts, circular cutting follows a radial pattern, allowing garments to flow naturally around the body. This fabric is widely used in apparel where comfort, flexibility, and symmetry are critical, such as T-shirts, skirts, babywear, and casual garments.

The term can describe both the fabric production method, such as circular knitting of cotton yarns, and the cutting method applied during garment manufacturing. In both cases, the goal is to enhance fabric performance while minimizing waste and improving wearability.

How Circular Cut Cotton Fabric Is Manufactured

The manufacturing of circular cut cotton fabric typically begins with high-quality cotton yarn, which may be combed or carded depending on the desired softness and durability. Circular knitting machines or rotary cutting systems are then used to create fabric panels or garment components with consistent tension and shape.

Circular Knitting Process

In circular knitting, cotton yarn is fed into a round knitting machine that produces a continuous tube of fabric. This method eliminates side seams and ensures even distribution of stretch. The resulting fabric is especially suitable for garments that require close body contact and long-term comfort.

Circular Cutting Technique

For woven cotton fabrics, circular cutting is applied during garment production. Fabric layers are stacked and cut in a radial pattern using precision rotary cutters or CNC cutting machines. This approach reduces fabric distortion and improves drape, particularly in flared or bias-sensitive designs.

Key Characteristics of Circular Cut Cotton Fabric

Circular cut cotton fabric offers distinct physical and functional properties that differentiate it from conventional cotton fabrics. These characteristics make it a preferred choice for both manufacturers and designers focusing on comfort-driven products.

- Enhanced drape and fluid movement due to radial fabric orientation

- Reduced seam pressure and improved garment symmetry

- Natural breathability and moisture absorption from cotton fibers

- Better resistance to twisting and deformation after washing

Advantages Over Traditional Straight-Cut Cotton Fabric

Compared with straight-cut cotton fabric, circular cut cotton fabric provides functional benefits that directly impact garment quality and consumer satisfaction. These advantages are especially noticeable in everyday apparel and performance-oriented casual wear.

| Aspect | Circular Cut Cotton | Straight-Cut Cotton |

| Drape | Smooth and natural | More rigid |

| Comfort | High, evenly distributed tension | Moderate, seam-focused stress |

| Fabric Waste | Lower with optimized layouts | Higher in complex designs |

Common Applications of Circular Cut Cotton Fabric

Circular cut cotton fabric is widely applied across multiple apparel categories due to its balance of comfort, durability, and aesthetic appeal. Manufacturers often select this fabric for products that require repeated washing and long-term wear.

Casual and Everyday Apparel

T-shirts, casual dresses, skirts, and loungewear frequently use circular cut cotton fabric. The fabric’s ability to conform naturally to body movement improves comfort and reduces garment distortion over time.

Children’s and Baby Clothing

Softness and breathability are critical in babywear. Circular cut cotton fabric minimizes seam irritation and allows freedom of movement, making it ideal for infants and young children.

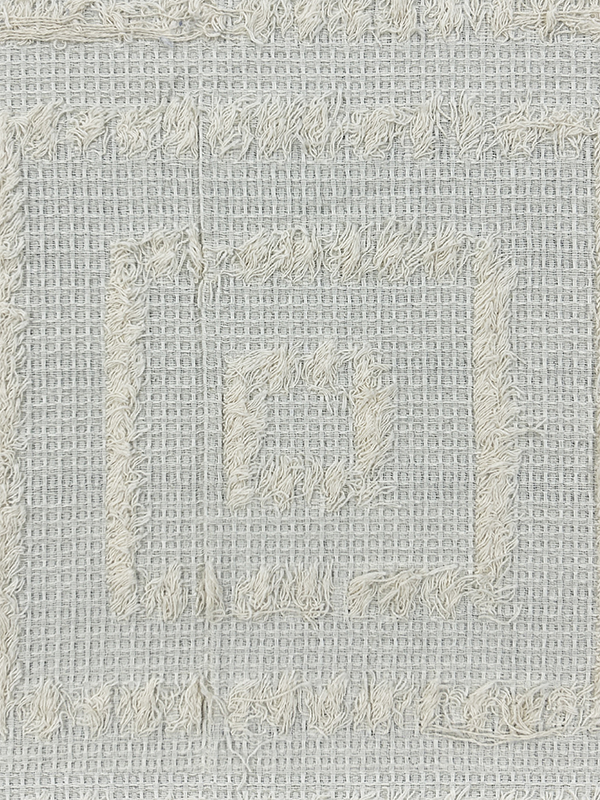

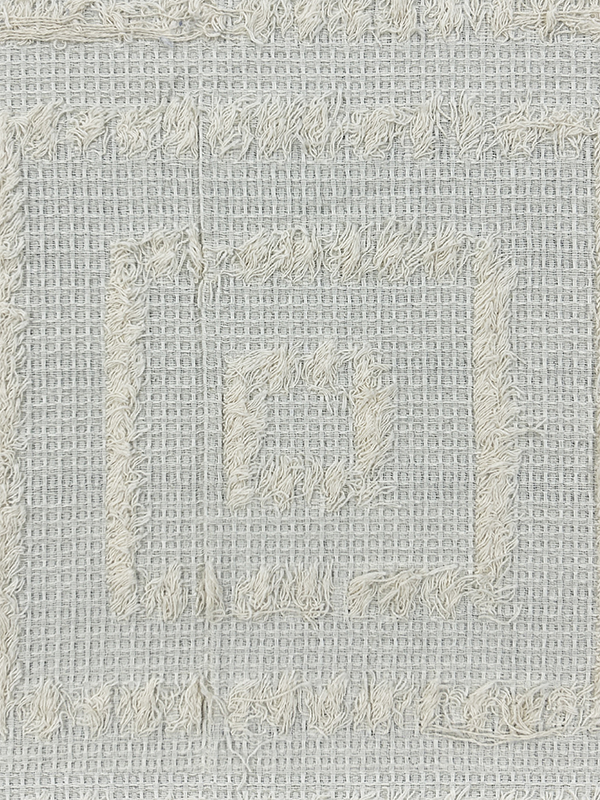

Home and Lifestyle Textiles

Some home textiles, such as lightweight cotton throws or decorative covers, also benefit from circular cutting techniques to enhance visual flow and reduce fabric stress points.

How to Choose the Right Circular Cut Cotton Fabric

Selecting the right circular cut cotton fabric requires careful evaluation of fiber quality, fabric weight, and end-use requirements. Making informed choices helps manufacturers maintain consistent product quality and reduce production issues.

- Check cotton grade and yarn count to ensure softness and durability

- Match fabric weight to garment function, such as lightweight for summer wear

- Confirm compatibility with circular knitting or cutting equipment

- Evaluate shrinkage and colorfastness after washing tests

Care and Maintenance Considerations

Proper care ensures that circular cut cotton fabric maintains its shape and comfort over time. While cotton is generally easy to maintain, circularly cut or knitted structures require attention to washing and drying methods.

Gentle washing cycles, moderate water temperatures, and low-heat drying are recommended to preserve fabric elasticity and prevent distortion. These practices help extend garment lifespan and maintain a consistent appearance.

Future Trends in Circular Cut Cotton Fabric

As apparel manufacturers focus on sustainability and efficiency, circular cut cotton fabric is expected to gain broader adoption. Improved cutting technologies, digital pattern design, and eco-friendly cotton sourcing are shaping the next generation of cotton textiles.

With increasing demand for comfortable, durable, and environmentally responsible garments, circular cut cotton fabric will continue to play a key role in modern textile production and design innovation.

English

English 中文简体

中文简体 Español

Español عربى

عربى