Pure cotton bedding fabric has remained the gold standard in sleep textiles for generations, offering a combination of natural properties that synthetic materials struggle to replicate. The inherent breathability, moisture-wicking capabilities, and hypoallergenic nature of cotton fibers create an optimal microclimate for restful sleep throughout the year. As consumers become increasingly aware of the connection between sleep quality and overall wellness, understanding the specific advantages of 100% cotton bedding fabric helps in making informed purchasing decisions that can significantly impact nightly rest and long-term health.

The cellular structure of cotton fibers provides natural temperature regulation that adapts to body heat and environmental conditions. Unlike synthetic polyester blends that trap heat and create clammy sensations, cotton's hollow fiber structure allows air to circulate freely while absorbing excess moisture from perspiration. This dual action keeps sleepers comfortable in both warm and cool conditions, reducing the nighttime restlessness caused by temperature fluctuations. Medical research has consistently shown that maintaining optimal body temperature during sleep is crucial for entering and sustaining deep sleep stages, making fabric choice a significant factor in sleep quality.

Beyond comfort, 100% cotton bedding fabric offers practical durability advantages that make it economically sensible despite higher initial costs compared to synthetic alternatives. Quality cotton fibers strengthen when wet, allowing for regular hot water washing without degradation. The material withstands repeated laundering cycles that would break down synthetic fibers, maintaining softness and integrity for years when properly cared for. This longevity, combined with the timeless appeal of natural cotton textures, makes pure cotton bedding a worthwhile investment for those prioritizing both sleep quality and long-term value.

Decoding Thread Count and Its Real Impact on Quality

Thread count has become a primary marketing metric in bedding sales, yet widespread misunderstanding surrounds what this number actually indicates about fabric quality. Thread count refers to the total number of horizontal and vertical threads woven into one square inch of fabric. While higher thread counts generally correlate with softer, more durable fabrics, the relationship is not linear, and excessively high thread counts can actually indicate inferior quality through manipulative counting methods or the use of low-quality multi-ply yarns.

Legitimate high-quality cotton bedding typically ranges from 200 to 800 thread count. Fabrics in the 300-500 range often provide the optimal balance of softness, breathability, and durability for most sleepers. Thread counts advertised above 1000 should be viewed skeptically, as single-layer weaving technology has practical limits. Manufacturers sometimes achieve inflated numbers by counting multi-ply yarns as multiple threads or using extremely fine, weak fibers that create high counts but poor performance.

| Thread Count Range | Characteristics | Best For |

| 200-300 | Crisp, breathable, budget-friendly | Hot sleepers, warm climates |

| 300-500 | Balanced softness and breathability | All-season comfort, general use |

| 500-800 | Luxuriously soft, smooth texture | Premium comfort, cooler climates |

| Above 800 | Often misleading marketing claims | Requires careful quality verification |

The quality of individual cotton fibers matters as much as thread count. Long-staple cotton varieties like Egyptian, Pima, and Supima produce stronger, smoother yarns that create superior fabrics regardless of thread count. These premium cottons feature fiber lengths of 1.5 inches or greater, compared to standard cotton fibers measuring less than 1 inch. The longer fibers allow spinning of finer, stronger yarns with fewer fiber ends protruding from the surface, resulting in smoother fabric with reduced pilling and improved durability.

Understanding Different Cotton Weave Structures

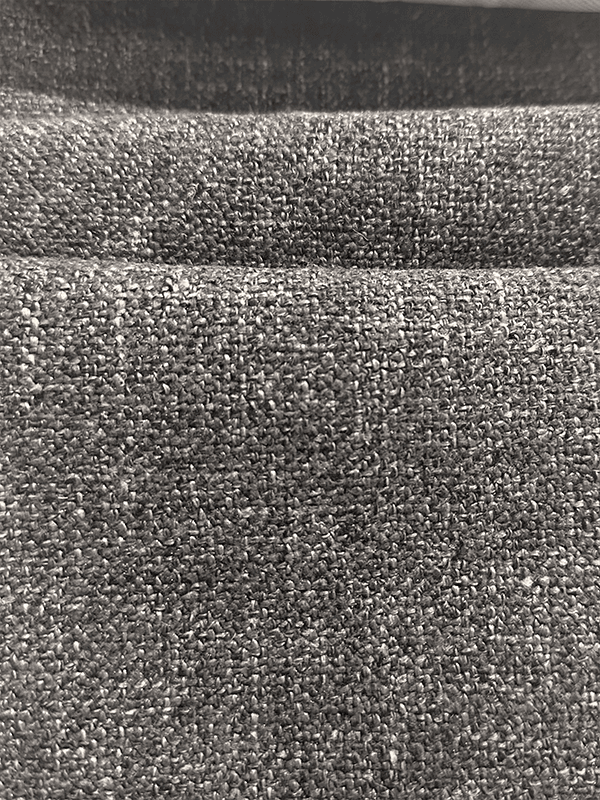

The weave pattern employed in manufacturing cotton bedding fabric profoundly affects the material's feel, appearance, durability, and performance characteristics. While thread count receives more marketing attention, weave structure often has a greater impact on the sleeping experience and fabric longevity. The three primary weave types used in cotton bedding each create distinct textures and performance profiles suited to different preferences and applications.

Percale weave follows a simple one-over-one-under pattern that creates a matte finish with a crisp, cool hand feel. This tight, balanced weave produces durable fabric with excellent breathability, making percale cotton ideal for warm sleepers or hot climates. The fabric maintains a smooth surface that resists pilling and wears evenly over time. Percale typically feels somewhat stiff when new but softens beautifully with washing, developing a lived-in comfort that improves with age. The weave structure requires thread counts between 200-400 to achieve optimal performance, with higher counts in percale sometimes reducing breathability without proportional comfort gains.

Sateen weave employs a four-over-one-under or three-over-one-under pattern that exposes more thread surface, creating a lustrous sheen and silky smooth texture. This weave produces fabric with a subtle drape and luxurious feel that many sleepers prefer. The increased surface exposure of threads makes sateen slightly less durable than percale, though quality sateen still provides years of service. The weave structure also makes sateen somewhat less breathable than percale, as the floating threads create a denser surface. Sateen fabrics typically use thread counts from 300-600, with the weave structure itself contributing significantly to the soft hand feel.

Specialty Weaves and Their Applications

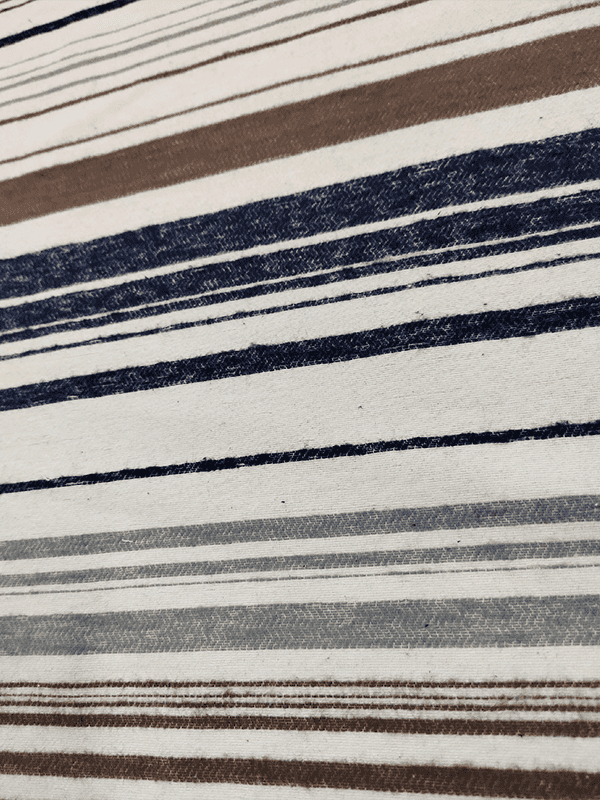

Twill weave creates a diagonal rib pattern recognizable from denim and chino fabrics. While less common in bedding than percale or sateen, twill cotton offers exceptional durability and wrinkle resistance. The diagonal weave structure distributes stress across the fabric more evenly than plain weaves, making twill particularly resistant to tearing and wear. This durability makes twill cotton suitable for heavy-use applications like dormitories, vacation rentals, or children's bedding where fabric must withstand intensive washing and rough treatment.

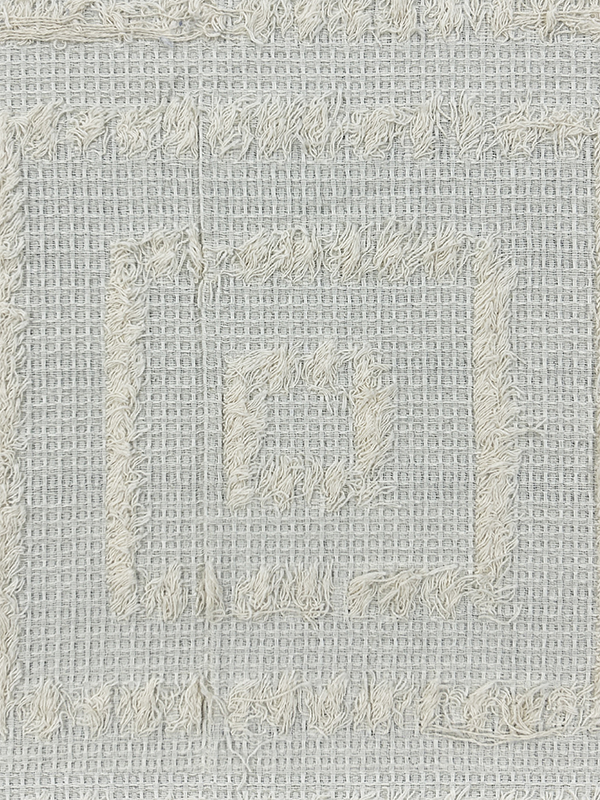

Jersey knit represents a different construction method entirely, using knitting rather than weaving to create stretchy, soft cotton fabric similar to t-shirt material. Jersey cotton bedding offers unmatched softness from the first use, requiring no break-in period. The fabric's natural stretch provides a cozy, enveloping feel that some sleepers find particularly comforting. However, jersey's loose knit structure makes it less durable than woven alternatives and more prone to pilling and stretching over time. The material works well for fitted sheets where its elasticity helps maintain secure fit but may be less suitable for flat sheets or duvet covers where structural stability matters more.

The Difference Between Cotton Types and Growing Regions

Not all cotton is created equal, and the variety and growing region significantly influence the final fabric's quality characteristics. Egyptian cotton, grown in the Nile River Valley, benefits from unique climate conditions that produce extra-long-staple fibers renowned for exceptional softness and strength. Authentic Egyptian cotton must be verified through certifications, as the term has been misused in marketing. Genuine Egyptian cotton creates luxurious bedding with superior durability, though premium pricing reflects the limited growing region and specialized cultivation requirements.

Pima cotton, cultivated primarily in the southwestern United States, Australia, and Peru, produces long-staple fibers comparable in quality to Egyptian cotton. The fiber length, typically 1.5 inches or greater, allows spinning of smooth, strong yarns that resist pilling and breakage. Supima represents a certification mark for American-grown Pima cotton, guaranteeing fiber quality and origin. Supima cotton bedding offers an excellent balance of quality and value, providing many of Egyptian cotton's benefits at more accessible price points.

Upland cotton accounts for approximately 90% of global cotton production and exhibits shorter fiber lengths than premium varieties. While capable of producing comfortable, serviceable bedding, Upland cotton fabrics generally feel less smooth and may show more pilling over time compared to long-staple alternatives. However, advances in spinning and finishing technologies have improved Upland cotton bedding quality significantly, making it a viable option for budget-conscious consumers who still want natural fiber benefits.

Proper Care and Maintenance for Longevity

Maintaining 100% cotton bedding fabric properly ensures maximum lifespan while preserving the material's desirable characteristics. Cotton's natural durability means that proper care can keep quality bedding performing well for five to ten years or longer. The care regimen begins with initial preparation—new cotton bedding should be washed before first use to remove manufacturing residues, soften fibers, and allow initial shrinkage to occur in a controlled manner.

Washing frequency depends on individual preferences and environmental factors, but most sleep experts recommend weekly washing for sheets and pillowcases that contact skin directly. Cotton can withstand hot water washing, which provides superior sanitization and deep cleaning compared to cold water cycles. However, warm water often suffices for routine cleaning while conserving energy and reducing fabric stress. Mild detergents without harsh chemicals or brighteners preserve fiber integrity and prevent buildup that can make fabrics feel stiff or scratchy.

Specific care practices that extend cotton bedding lifespan include:

- Avoiding overloading washing machines, which prevents adequate water circulation and can cause excessive wrinkling and uneven cleaning

- Using the gentle or permanent press cycle for high-thread-count fabrics to minimize mechanical stress during agitation and spinning

- Removing bedding promptly from the dryer while slightly damp to reduce wrinkles and make bed-making easier

- Line drying when possible, which saves energy, reduces heat damage, and imparts a fresh outdoor scent while preventing dryer-related shrinkage

- Rotating multiple sheet sets to distribute wear evenly and allow fabrics to rest between uses, which helps fibers recover and extends overall lifespan

Addressing Common Concerns About Cotton Bedding

Despite cotton's popularity, certain concerns frequently arise regarding pure cotton bedding fabric that deserve thoughtful examination. Wrinkling represents the most common complaint, as cotton naturally creases during washing and use. While some embrace this characteristic as part of cotton's organic, relaxed aesthetic, others find excessive wrinkling unacceptable. The tendency to wrinkle varies significantly based on weave type, thread count, and finishing treatments applied during manufacturing.

Percale weaves generally wrinkle more than sateen weaves due to their simpler structure and crisper texture. Higher thread counts within the same weave type typically wrinkle less than lower counts because of increased fabric density. Some manufacturers apply wrinkle-resistant finishes to cotton bedding, though these treatments may involve chemical processes that some consumers wish to avoid. For those sensitive to wrinkles but committed to natural fibers, removing bedding from the dryer promptly and smoothing it onto the bed while still slightly warm minimizes creasing effectively.

Shrinkage concerns also merit attention when purchasing 100% cotton bedding. Natural cotton fibers shrink when exposed to heat and moisture, with the greatest shrinkage occurring during initial washes. Quality manufacturers pre-shrink fabrics during production and cut bedding oversized to account for residual shrinkage. Consumers should verify that products are labeled as pre-shrunk and follow care instructions carefully, particularly avoiding high dryer heat that can cause additional shrinkage beyond expected levels. Purchasing sheets with deep pockets and generous dimensions provides insurance against shrinkage affecting fit.

Organic Cotton Versus Conventional Cotton Considerations

The distinction between organic and conventional cotton bedding extends beyond agricultural practices to encompass health, environmental, and ethical considerations that influence purchasing decisions for many consumers. Organic cotton cultivation prohibits synthetic pesticides, herbicides, and fertilizers, relying instead on natural pest management, crop rotation, and organic soil amendments. This approach reduces environmental contamination of water sources and soil while eliminating pesticide residues that might remain in finished fabrics.

From a performance standpoint, organic and conventional cotton fabrics exhibit similar characteristics when manufactured to comparable quality standards. The primary differences relate to chemical exposure during cultivation and processing rather than inherent fiber properties. Organic certification programs like GOTS (Global Organic Textile Standard) regulate not only agricultural practices but also subsequent processing, requiring that dyeing, finishing, and manufacturing meet strict environmental and social responsibility criteria. This comprehensive oversight provides assurance that organic cotton bedding minimizes chemical exposure throughout the entire production chain.

The price premium for organic cotton bedding typically ranges from 20% to 50% above comparable conventional cotton products. This additional cost reflects certification expenses, generally lower crop yields in organic agriculture, and smaller production volumes compared to mainstream conventional cotton. Consumers must weigh personal values regarding environmental impact, chemical exposure concerns, and support for sustainable agriculture against budget constraints. For those with chemical sensitivities or strong environmental commitments, the premium may represent worthwhile investment, while others may find conventional cotton from reputable manufacturers meets their needs adequately.

Identifying Quality Indicators When Shopping

Navigating the bedding marketplace requires understanding quality indicators beyond marketing claims and attractive packaging. Savvy consumers can identify superior cotton bedding through several telltale signs that reveal manufacturing quality and material authenticity. The fabric's hand feel provides immediate quality feedback—quality cotton should feel smooth and substantial, without thin spots, excessive stiffness, or papery texture. Holding fabric to light reveals weave consistency, with quality products showing uniform thread spacing without gaps or irregularities.

Product labeling and certifications offer valuable quality assurance when properly understood. The "100% cotton" label confirms fiber content but doesn't guarantee quality level. Additional certifications provide more specific assurances. OEKO-TEX Standard 100 certification verifies that fabrics have been tested for harmful substances and meet human-ecological requirements. This independent testing covers pesticide residues, formaldehyde, heavy metals, and other potentially harmful chemicals that might persist in finished textiles.

Stitching quality and construction details reveal manufacturing standards that affect durability and performance. Deep pocket corners on fitted sheets should feature strong elastic that maintains grip without excessive tension that could cause tearing. Seam allowances should be substantial and finished properly to prevent fraying. Quality manufacturers use reinforced stitching at stress points and employ tight, even stitch spacing throughout. Examining these construction details in-store or through detailed product images helps distinguish well-made products from those cutting corners to achieve lower price points.

Seasonal Considerations and Climate Adaptation

While 100% cotton bedding fabric performs admirably across seasons, strategic selection of specific cotton types and weaves can optimize comfort for different climate conditions and personal temperature preferences. Understanding how various cotton characteristics interact with seasonal temperature variations allows consumers to build bedding collections that provide ideal comfort year-round.

Summer bedding benefits from lighter-weight cotton in percale weaves with thread counts in the 200-400 range. These specifications maximize breathability and moisture-wicking while maintaining the crisp, cool feel that promotes comfortable sleep in warm conditions. Lighter colors reflect heat rather than absorbing it, providing marginal but noticeable temperature benefits. Some sleepers prefer even lighter cotton voile or gauze weaves during peak summer months, though these specialty fabrics may sacrifice some durability for enhanced airflow.

Winter bedding can transition to heavier cotton fabrics in sateen weaves with thread counts in the 400-600 range. The denser construction and lustrous weave structure provide slightly more warmth while maintaining cotton's essential breathability. Flannel represents another winter option, featuring cotton fibers that have been brushed to create a soft, fuzzy surface that traps warm air. Quality cotton flannel provides cozy warmth without the overheating associated with synthetic fleece, allowing the material to breathe and prevent the clammy sensation that can disrupt sleep.

Color Fastness and Dye Quality in Cotton Bedding

The colorfastness of cotton bedding fabric significantly impacts both aesthetic longevity and practical care requirements. Quality dyeing processes ensure that colors remain vibrant through repeated washing without fading, bleeding, or transferring to other fabrics. Reactive dyes, which form chemical bonds with cotton fibers, provide superior colorfastness compared to direct or vat dyes that simply coat fiber surfaces. The dye quality and application method used during manufacturing directly affects how well bedding maintains its appearance over years of use.

Fiber-reactive dyeing creates permanent color that becomes part of the cotton fiber structure rather than a surface coating. This integration means that color persists even as surface fibers wear away, preventing the faded, washed-out appearance that develops in poorly dyed fabrics. The process requires more time and precision than cheaper alternatives, contributing to higher costs in quality bedding. Testing colorfastness before purchase is difficult, but reputable manufacturers provide care instructions that would be overly conservative if their dyes were prone to bleeding or fading.

White and light-colored cotton bedding presents unique considerations regarding brightness maintenance and resistance to yellowing. Optical brighteners added during manufacturing make whites appear brilliant initially but can yellow with sun exposure or react with chlorine bleach to create permanent discoloration. Quality white cotton bedding relies on superior fiber quality and proper bleaching processes during manufacturing rather than excessive brightening agents. Washing white cotton in hot water with appropriate oxygen-based bleaches maintains brightness without the fiber damage that chlorine bleach can cause.

Health and Allergen Considerations

The hypoallergenic properties of 100% cotton bedding fabric make it particularly suitable for individuals with sensitivities, allergies, or respiratory conditions. Cotton's natural composition resists dust mite colonization better than synthetic materials, as the fibers don't provide the same favorable environment for these common allergens. The ability to wash cotton in hot water—temperatures exceeding 130°F that kill dust mites and denature allergenic proteins—provides a significant health advantage for allergy sufferers.

Chemical sensitivity concerns make pure cotton appealing for those reacting to synthetic materials or finishing treatments. However, even 100% cotton bedding may contain residual processing chemicals unless specifically certified as free from harmful substances. GOTS certification or OEKO-TEX Standard 100 certification provides independent verification that fabrics meet strict limits for chemical residues, offering peace of mind for chemically sensitive individuals or parents concerned about infant exposure to potentially harmful substances.

The breathability of cotton also contributes to healthier sleep environments by reducing moisture accumulation that can promote mold, mildew, and bacterial growth. Cotton's moisture-wicking properties pull perspiration away from skin and allow it to evaporate, keeping the sleep surface drier and less hospitable to microorganisms. This moisture management becomes particularly important for individuals who experience night sweats or live in humid climates where moisture control is essential for maintaining sanitary bedding conditions. Regular washing in hot water, combined with thorough drying, ensures that cotton bedding remains hygienically clean and supports healthy sleep environments for years of use.

English

English 中文简体

中文简体 Español

Español عربى

عربى